The role of cold rolling mill is to pickling the surface of steel plate to remove rust and anti-rust treatment. Through the mobile explosion-proof intelligent wheeled robot, Tianchuang robot can accurately identify various instrument readings, the appearance and temperature status of the equipment, timely find the internal defects of the equipment, replace the manual high-frequency autonomous inspection, and achieve unmanned duty and digital control.

Low Timeliness

The workload of inspection operation and maintenance personnel is large, the inspection frequency and quality of key areas cannot be guaranteed, and the timeliness of detection information feedback is low

Wrong Detection, Missing Detection

Manual inspection is difficult to manage and standardize, to ensure that the spot inspection is in place, and there will often be missed detection, wrong detection, and false detection

Safety Hazard

There are hydrochloric acid steam and smoke, and the working environment is relatively harsh, which has certain safety risks for inspection and operation and maintenance personnel

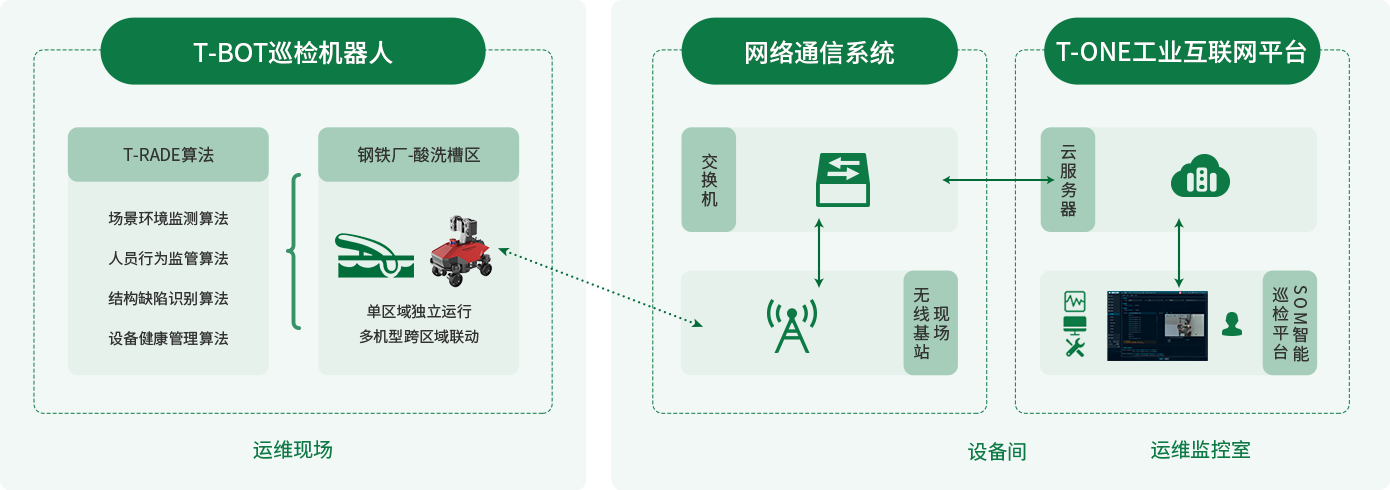

The regional solution of Tianchuang robot cold rolling plant is based on the explosion-proof wheeled robot that integrates advanced technologies such as artificial intelligence, big data, comprehensive monitoring and fault diagnosis, and carries out all-weather autonomous inspection for motor equipment, meter switch loading and environment in the region. Remote real-time monitoring and equipment status data analysis and management through the intelligent inspection system platform, to fully grasp the operation of electrical, meter and other equipment.

Edge cloud collaboration, unified management

Data collection is uploaded in real time to form a digital inspection ledger

Inspection data trend analysis, visual presentation

The inspection work has changed from regular on-site inspection to unmanned, all-weather inspection of equipment status

Create a safe environment and reduce operational risks

Meter switch identification

Environmental monitoring

Equipment operation status monitoring

Product support

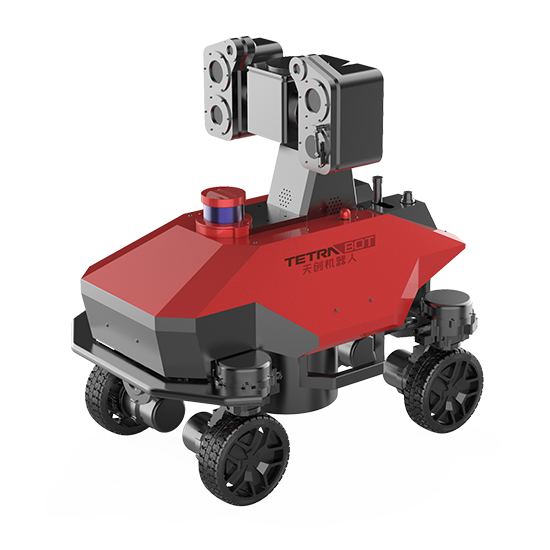

T9-W Explosion-Proof Wheeled Robot

Products have the infrared thermal imaging temperature measurement, laser combustible gas detection, flame detection, and gas concentration detection, and realize autonomous unmanned inspection in the energy hazardous chemical industry.View details

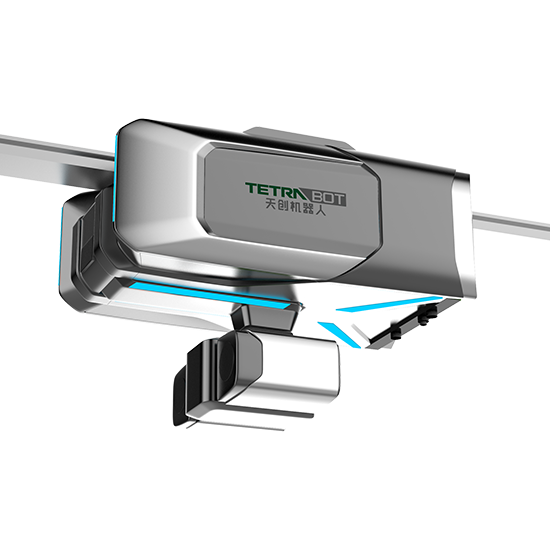

T3-C Hanging Monorail Robot

The product can monitor environmental information and equipment in a long distance underground pipeline gallery and release fire alarms. By centralized control platform, it can realize the control, data access, statistical analysis and multi-dimensional visual display of inspection robot.View details

T-ONE™ SOM Intelligent Inspection Platform

View details

T-RADE Intelligent Algorithm

The T-RADE intelligent algorithm, based on a large amount of experience and technical accumulation in intelligent inspection and operation of segmented scenarios, forms a multi class configurable algorithm model at the application level, forming a powerful AI algorithm library. Ability to quickly deploy and build high-performance AI algorithm application capabilities for enterprises.View details

Application Scenario Case