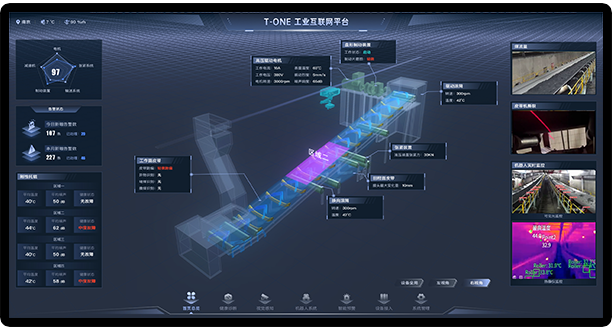

T-ONE™ SOM Intelligent Inspection Platform

With the support of rich communication protocols, fully integrate multi-dimensional data from industrial sites, introduce digital twins, data visualization and other means to intuitively display on-site working conditions, apply multi-sensor fusion technology and data analysis technology to deeply explore data applications, and create a user-friendly and integrated intelligent inspection new platform.

Core Competence

AI Capability

Support edge computing, data storage and data synchronization; Support edge deployment and real-time application of machine learning and AI analysis models, enabling advanced data analysis and real-time decision-making.

Rule Engine

A rule engine created based on real-world scenarios, triggering conditions, and job content, with real-time device condition triggering and timed event triggering, to achieve complex strategy processing and other job content.

Operation Monitoring

Real time video surveillance providing basic operational information for different scenarios, freely switching monitoring devices, and conducting fixed-point queries based on resource areas and regions.

Operation Monitoring

Real time video surveillance providing basic operational information for different scenarios, freely switching monitoring devices, and conducting fixed-point queries based on resource areas and regions.

Diagnostic Warning

Provide a platform display for status monitoring, fault diagnosis, alarm statistics, and lifecycle management through periodic statistics of device operating status.

Value Advantage

Flexible Configuration

Flexible configuration of applications, processes, indicators, and reports to meet customized needs

Application Ability

Provide multi-dimensional visualization modules and rich controls to quickly build industrial applications

Component Extension

Support uploading algorithm code generation of custom algorithm components and cross-team collaboration

Three-Dimensional Modeling

Quickly build various hierarchical 3D models based on scene requirements

Data Collaboration

Data collection in real time to keep abreast of equipment operating status

Modular System

Loose coupled structure is built, highly scalable, and integrates more phased business systems

Monitoring and Analysis

Real-time warning of equipment abnormal conditions reduces the probability of unplanned downtime

Internet of Everything

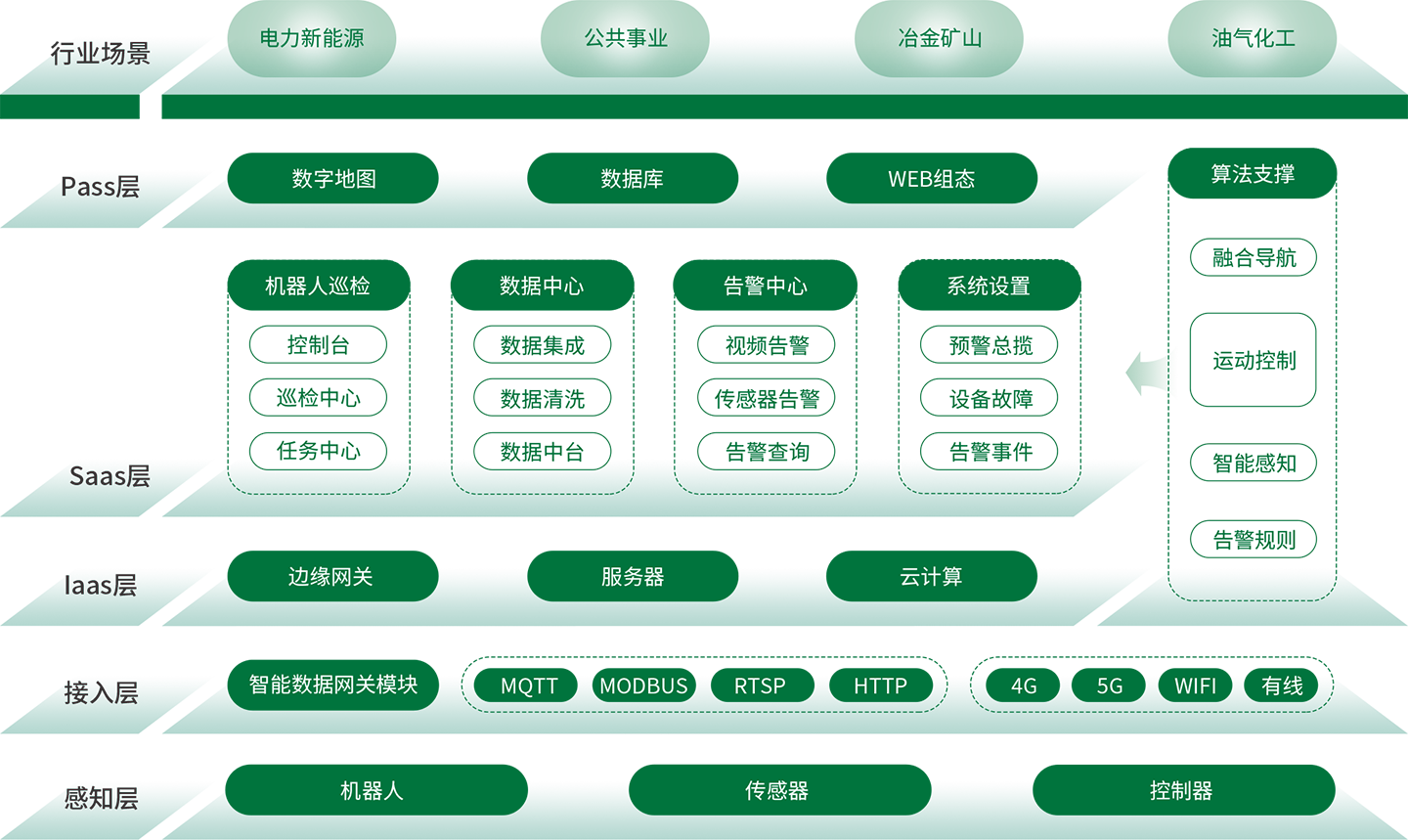

Access and fusion of multiple and heterogeneous data sources, connecting different sensing layer devicesSystem Architecture

Application Scenario Case