The methanol workshop of chemical plant is used for the synthesis of methanol in the daily production link, which belongs to the flammable and explosive high-risk working environment. The intelligent operation and maintenance solution of Tianchuang robot can accurately grasp the operation status of equipment at any time, eliminate the hidden dangers of equipment failure in the germination state to the maximum extent, reduce the loss of failure, ensure the safe operation of equipment, promote the intelligent and digital development of enterprises, help build a five-in-one safety prevention and control system that is known, visible, traceable and controllable, and continue to improve the intrinsic safety capability of chemical industry.

Low Inspection Accuracy

Manual inspection depends on experience, individual difference is large, equipment status detection is not accurate

Hazardous Working Environment

Manual inspection of hazardous working environments, such as flammable, explosive, and harmful gases, poses safety risks

High-Intensity Work

Many equipment, complex layout, manual spot inspection labor intensity, low efficiency, easy to miss and false inspection, inspection quality can not be guaranteed

Tianchuan Robot Chemical plant methanol workshop intelligent inspection solution to adapt to the extreme environment of special robots, big data, edge computing, AI recognition algorithm, 5G integration as the basis for the realization of pipeline, tank and other equipment monitoring and early warning, meter valve switch and other status recognition and personnel behavior supervision in one of the unattended digital operation and maintenance control system.

Edge cloud collaboration, unified management

Data collection is uploaded in real time to form a digital inspection ledger

Inspection data trend analysis, visual presentation

The inspection work has changed from regular on-site inspection to unmanned, all-weather inspection of equipment status

Create a safe environment and reduce operational risks

Monitoring and early warning of dangerous sources such as methanol liquefaction tanks

Rapid acquisition of equipment temperature, vibration, flow, pressure and other data

Pipe leakage identification and monitoring

Product support

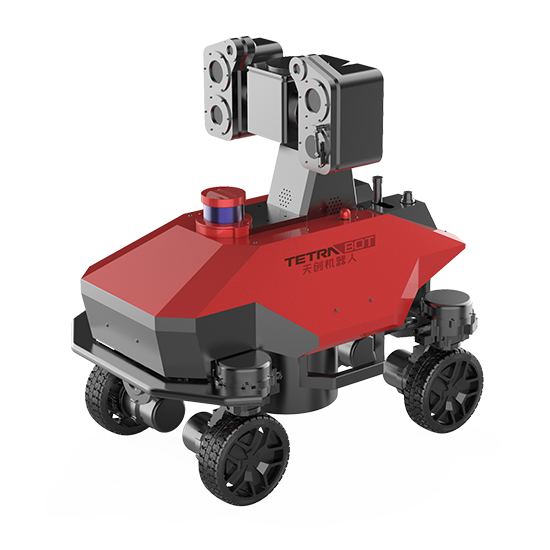

T9-W Explosion-Proof Wheeled Robot

Products have the infrared thermal imaging temperature measurement, laser combustible gas detection, flame detection, and gas concentration detection, and realize autonomous unmanned inspection in the energy hazardous chemical industry.View details

T9-R Explosion-Proof Hanging Monorail Robot

The product is equipped with HD cameras and infrared thermal imagers, integrated gas detection, temperature and humidity, flame detection and other sensors, realize environmental information monitoring, gas monitoring and other functions as well as data storage, analysis and other 3D display for all Class II explosion-proof scenes.View details

Compound Explosion-Proof Multi-Function PTZ

View details

Explosion-Proof Multi-Functional PTZ

View details

T-ONE™ SOM Intelligent Inspection Platform

View details

T-RADE Intelligent Algorithm

The T-RADE intelligent algorithm, based on a large amount of experience and technical accumulation in intelligent inspection and operation of segmented scenarios, forms a multi class configurable algorithm model at the application level, forming a powerful AI algorithm library. Ability to quickly deploy and build high-performance AI algorithm application capabilities for enterprises.View details

Application Scenario Case