With the acceleration of the construction of natural gas pipeline network, a situation of many stations and dense network has been formed. Strengthening the safety management of natural gas terminals and preventing accidents has become the primary issue in production. According to the characteristics of the industry scene, Tianchuang robot provides natural gas onshore terminal solutions with intelligent inspection robots as the core, to realize the independent detection of the environment and equipment in the production area, and the drip inspection of key areas and high-risk areas of natural gas pipelines, so as to promote the development process of digital and intelligent natural gas terminal stations faster.

High Labor Cost

The manpower cost is large, at least 2-3 inspection personnel need to enter the station in a group, and must carry a lot of equipment, increase the burden of the body, affecting the inspection task

Quality Cannot Be Guaranteed

Operation and maintenance personnel professional skills and responsibility of individual differences, low efficiency, easy to miss and false inspection, inspection quality can not be guaranteed

High Risk

Manual inspection has a hidden danger of high labor intensity and high danger degree. Once a dangerous situation occurs, the life safety of inspection personnel will be threatened, and it is impossible to deal with the dangerous situation

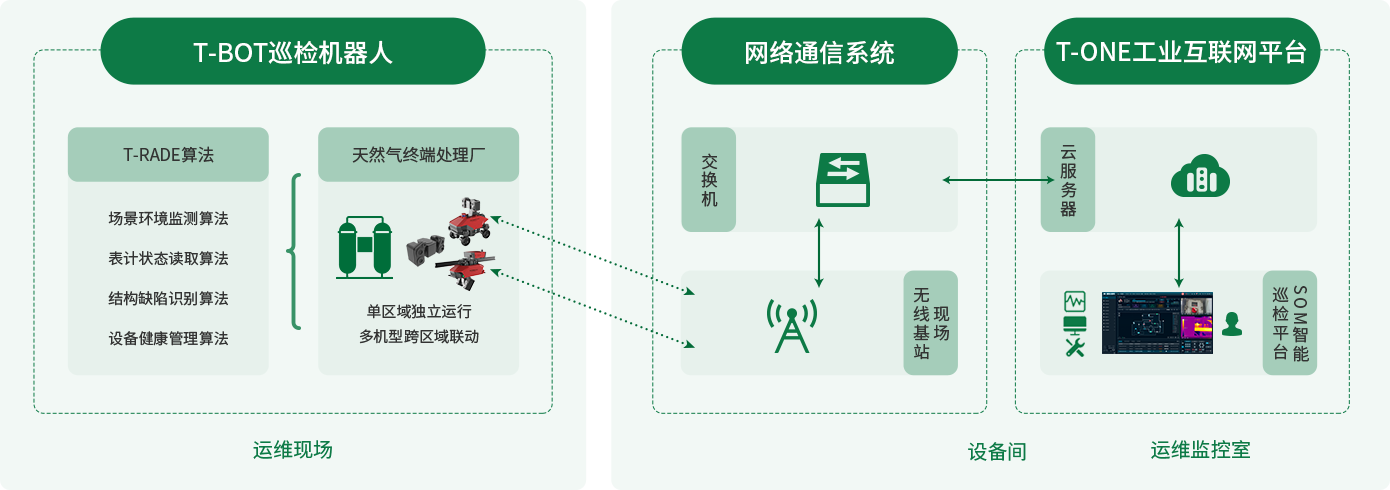

The intelligent inspection solution of Tianchuangrobot natural gas terminal treatment plant is based on the explosion-proof robot integrated with the intelligent algorithm of Tianchuangrobot, and combined with the visual data analysis system of T-ONE industrial Internet platform, it carries out daily autonomous inspection for the phenomena of area meter, combustible gas concentration, equipment operation and leakage of natural gas processing equipment. Improve the operation and maintenance personnel's perception, discovery, early warning and emergency handling capabilities on the scene, and realize a new model of intelligent explosion-proof inspection of natural gas onshore terminals.

Data are classified and stored in real time, which is convenient for fault query, statistics and judgment

Automatically generate inspection reports or reports, reducing the cost and time of manual selection of useful variables

Eliminate the individual differences of manual inspection, make the data more standard, and can be traced to history

The problems found during inspection and maintenance of pipe network are reported to the command and dispatch center in real time, realizing the efficient hidden danger detection mechanism of timely discovery, timely reporting, and timely handling

Complete on-site daily monitoring work with "machine replacement", greatly reduce enterprise operation and maintenance costs and personnel safety risks, reduce subjective and objective interference factors of monitoring results, and improve inspection quality

Product support

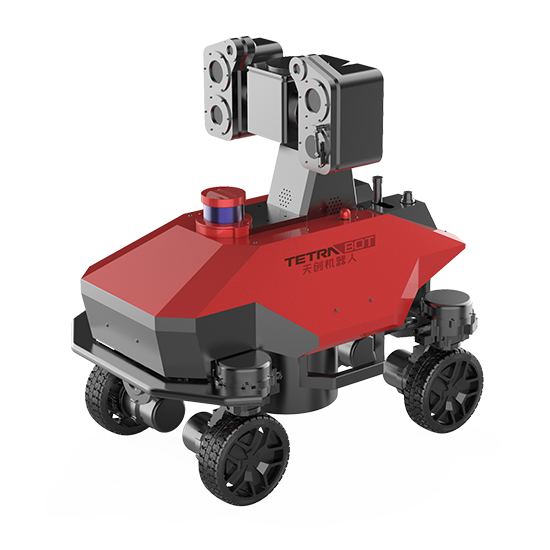

T9-W Explosion-Proof Wheeled Robot

Products have the infrared thermal imaging temperature measurement, laser combustible gas detection, flame detection, and gas concentration detection, and realize autonomous unmanned inspection in the energy hazardous chemical industry.View details

T9-R Explosion-Proof Hanging Monorail Robot

The product is equipped with HD cameras and infrared thermal imagers, integrated gas detection, temperature and humidity, flame detection and other sensors, realize environmental information monitoring, gas monitoring and other functions as well as data storage, analysis and other 3D display for all Class II explosion-proof scenes.View details

Compound Explosion-Proof Multi-Function PTZ

View details

Explosion-Proof Multi-Functional PTZ

View details

T-ONE™ SOM Intelligent Inspection Platform

View details

T-RADE Intelligent Algorithm

The T-RADE intelligent algorithm, based on a large amount of experience and technical accumulation in intelligent inspection and operation of segmented scenarios, forms a multi class configurable algorithm model at the application level, forming a powerful AI algorithm library. Ability to quickly deploy and build high-performance AI algorithm application capabilities for enterprises.View details