The water storage power station has two upper and lower reservoirs. It generates electricity and stores electricity by pumping/discharging water. It is the most reliable energy storage device in the power system and an important part of the development of new energy. Among them, the water turbine layer is the core area of the hydropower station. Tianchuang Robot Pumped Storage Power Station Inspection and Operation Solution The information-based intelligent inspection and control system with the robot as the core can realize inspection, data collection and classified storage of related equipment., modeling analysis, information push and other functions can truly reduce the pressure on operation and maintenance personnel, provide more accurate equipment status monitoring, improve the intelligence level of the power station, and improve equipment management level and work efficiency.

Low Inspection Consistency

Manual inspection is greatly influenced by individual experience, which is prone to erroneous inspections and missed inspections, causing potential safety hazards

Large Regional Span

Manual inspection takes a long time, and the working environment contains high temperatures, harmful gases, etc.

Wide Equipment Distribution

There are many electromechanical equipment, complex system structure, and many inspection points, making inspection difficult

The Tianchuang Robot Pumped Storage Power Station inspection and operation solution uses the ability of intelligent wheeled robots to move autonomously to conduct round-the-clock monitoring and monitoring of the operating equipment in the water turbine floor, accurately identify the switch status of meter valves, and discover equipment abnormalities or defects. Send an alarm in real time, allowing operation and maintenance personnel to evaluate the overall status of the water turbine unit without leaving home, and quickly locate vulnerable components and grasp the health status of the equipment in real time.

Edge cloud collaboration, unified management

Data collection and upload in real time to form a digital inspection ledger

Trend analysis of inspection data and visual presentation

The inspection work has been transformed from regular manual on-site inspections to unmanned, all-weather equipment status inspections

Create a safe environment and reduce operational risks

Equipment operating status monitoring

Identification of meter switch valve status

Comprehensive monitoring and early warning of abnormal conditions

Shorten fault discovery time and accurately locate fault points

Passive emergency repair transformed into active operation and maintenance

Product support

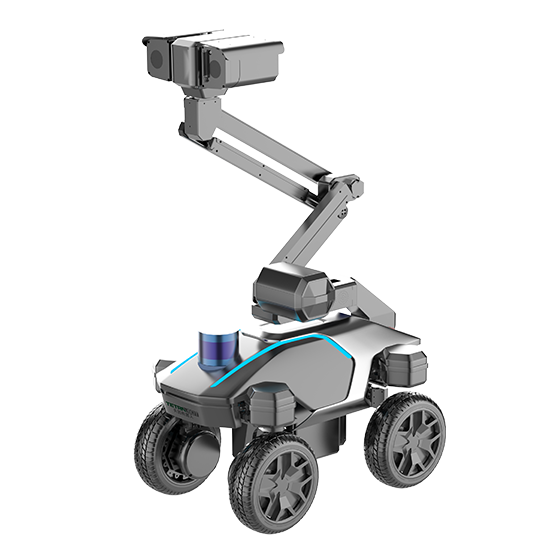

T7-S Wheeled Lifting Arm Robot

The product aims at wheeled intelligent inspection solution designed for industrial interior scenes. Robot has a high degree of autonomy and intelligence, and can detect various meter switches, equipment defects and abnormal behaviors.View details

T-ONE™ SOM Intelligent Inspection Platform

View details

T-RADE Intelligent Algorithm

The T-RADE intelligent algorithm, based on a large amount of experience and technical accumulation in intelligent inspection and operation of segmented scenarios, forms a multi class configurable algorithm model at the application level, forming a powerful AI algorithm library. Ability to quickly deploy and build high-performance AI algorithm application capabilities for enterprises.View details