Cable tunnels carry the key to power and energy transmission on the user side and are also an important part of the power system. Tianchuang Robot Cable Tunnel Intelligent Inspection Solution can realize real-time monitoring of the operating status and environmental conditions of equipment inside the tunnel, and has functions such as quickly and accurately locating cable fault locations and predicting tunnel fault risk trends. Build a three-in-one intelligent inspection system for cable tunnel detection, monitoring and early warning.

Heavy Workload

Cables, electrical boxes and other equipment in the area are continuously laid out, with many detection points, which is prone to missing inspections.

Environment Is Complex

The cable tunnel is located underground, has a closed space and a long distance, and manual inspection is time-consuming and labor-intensive

Low Inspection Consistency

There are large differences in individualization, and the reliability of inspection results is unstable

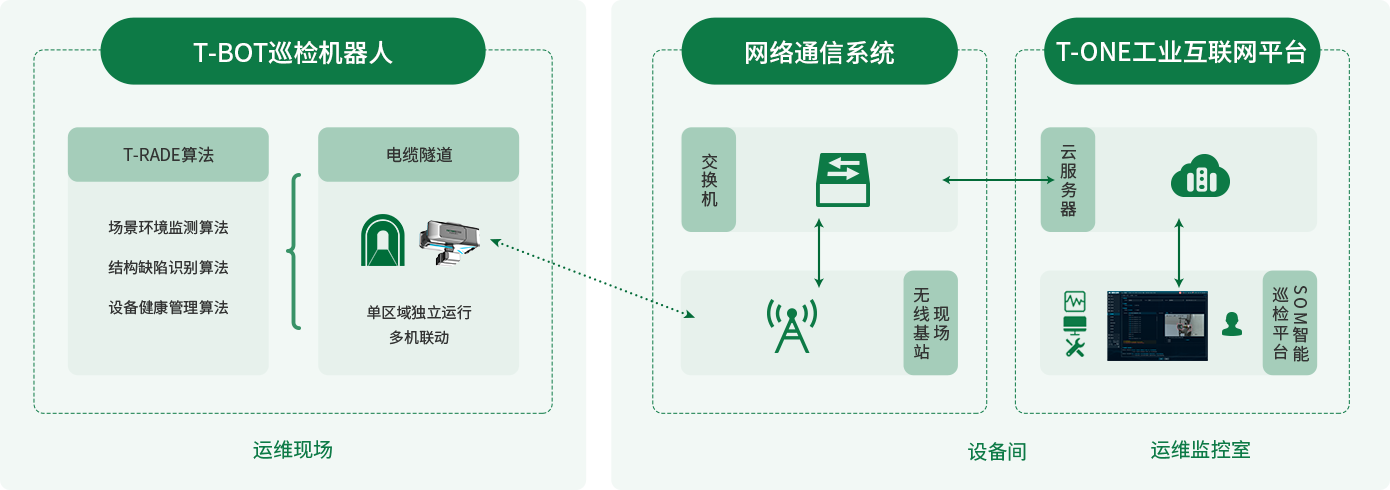

Tianchuang Robot Cable Tunnel Intelligent Inspection Solution uses an intelligent robot walking on track to inspect and diagnose the appearance of cables and other auxiliary equipment in the tunnel, and to monitor the overall operating environment status in the tunnel in real time, as well as lighting, water pump, water level, fan and other conditions in the tunnel. Monitor, and automatically save inspection data to the background of the system to generate a detection and analysis report, which is organically linked and combined with the monitoring system. This enables line operation and maintenance personnel to grasp the internal equipment and environmental conditions of the cable tunnel without leaving home, and realizes fully autonomous and unmanned intelligent inspection of high-voltage cables in the cable tunnel.

Edge cloud collaboration, unified management

Data collection and upload in real time to form a digital inspection ledger

Trend analysis of inspection data and visual presentation

The inspection work has been transformed from regular manual on-site inspections to unmanned, all-weather equipment status inspections

Create a safe environment and reduce operational risks

Equipment operating status monitoring

Comprehensive monitoring and early warning of abnormal conditions

Shorten fault discovery time and accurately locate fault points

Passive emergency repair transformed into active operation and maintenance

Product support

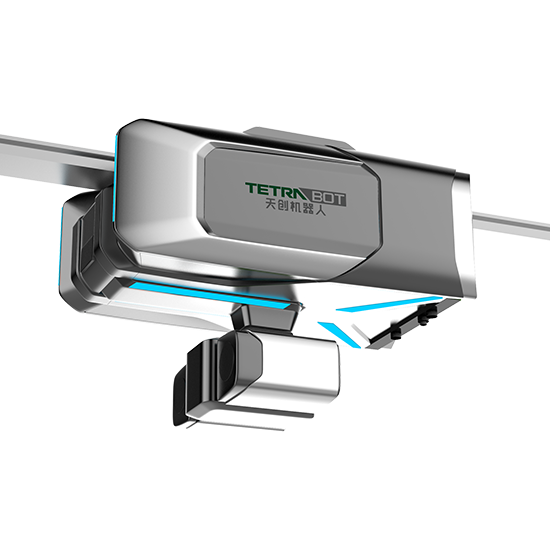

T3-C Hanging Monorail Robot

The product can monitor environmental information and equipment in a long distance underground pipeline gallery and release fire alarms. By centralized control platform, it can realize the control, data access, statistical analysis and multi-dimensional visual display of inspection robot.View details

T-ONE™ SOM Intelligent Inspection Platform

View details

T-RADE Intelligent Algorithm

The T-RADE intelligent algorithm, based on a large amount of experience and technical accumulation in intelligent inspection and operation of segmented scenarios, forms a multi class configurable algorithm model at the application level, forming a powerful AI algorithm library. Ability to quickly deploy and build high-performance AI algorithm application capabilities for enterprises.View details

Application Scenario Case