Tianchuang robot carries out automatic inspection for the mine underground water pump room site and equipment through the intelligent robot for mining rail, and transmits the inspection screen and monitored data to the ground inspection centralized control platform in real time, effectively helping the mine to improve the level of intelligent safety management, and provides strong support for promoting the safety development of "mechanized replacement, automatic reduction of personnel, and intelligent unmanned".

Low Timeliness

The workload of inspection operation and maintenance personnel is large, the inspection frequency and quality of key areas cannot be guaranteed, and the timeliness of detection information feedback is low

Inefficiency

The traditional mine safety inspection work has high manpower and material resources consumption, low efficiency, and can not be managed directly

Safety Hazard

The underground mine is a low-illumination, high-humidity, inflammable, explosive and dust environment, which has certain safety risks for inspection and maintenance personnel

Tianchuang robot mine underground water pump room intelligent inspection solution with mining rail robot as the core, in the realization of high-definition image acquisition, at the same time, equipped with sound, temperature, gas and other sensors, can real-time acquisition of field sound, temperature, environmental gas and other parameters, real-time data transmission to the operation and maintenance center background, and intelligent analysis of these data. An early warning can be issued when an anomaly is found, and the ground terminal staff can analyze and deal with the equipment failure in time according to the alarm information and equipment parameters. The inspection efficiency is improved, the labor intensity of employees is reduced, the operation risk is reduced, the efficiency is reduced, and the intelligent level of the mine is improved.

Edge cloud collaboration, unified management

Data collection is uploaded in real time to form a digital inspection ledger

Inspection data trend analysis, visual presentation

The inspection work has changed from regular on-site inspection to unmanned, all-weather inspection of equipment status

Create a safe environment and reduce operational risks

Meter switch identification

Environmental monitoring

Equipment operation status monitoring

Product support

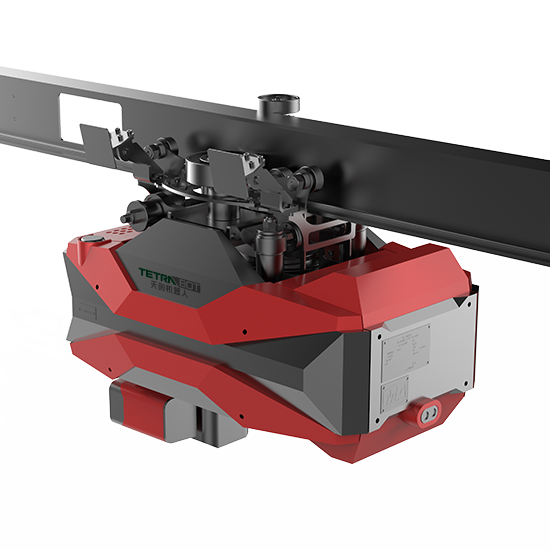

T9-C Hanging Monorail Robot For Mining

The product has mine coal safety certification, explosion-proof and intrinsic safety type. It's equipped with starlight HD camera, infrared thermal imager, gas sensor, ionic smoke, flame detection and other sensors, which can control underground environmental information in real time, and build underground intelligent inspection system.View details

T9-E Intrinsically Safe Hanging Monorail Robot For Mining

The product has the mine intrinsic safety type explosion-proof certification and lightweight design. The body integrates visible light camera, infrared thermal imager, environmental and gas monitoring sensors and other modules to accurately collect and measure the field equipment status and environmental conditions in mines.View details

T-ONE™ SOM Intelligent Inspection Platform

View details

T-RADE Intelligent Algorithm

The T-RADE intelligent algorithm, based on a large amount of experience and technical accumulation in intelligent inspection and operation of segmented scenarios, forms a multi class configurable algorithm model at the application level, forming a powerful AI algorithm library. Ability to quickly deploy and build high-performance AI algorithm application capabilities for enterprises.View details

Application Scenario Case