In the process of conveyor belt running in mine underground roadway, the roller and roller of belt conveyor are often damaged, the conveyor belt is suddenly torn, and the water in tunnel is accumulated, which causes direct and indirect economic losses. Tianchuang robot adopts coal safety certified mobile robot to monitor the operation of belt conveyor in real time, predict and warn the fault in advance, and reduce the downtime of the fault.

Narrow Space

The Working Space Is Characterized by Large Length, Undulating Turns and Narrow Space

Electromagnetic Interference

Electromagnetic and radio frequency interference near large electromechanical equipment,

Safety Hazard

The underground mine is a low-illumination, high-humidity, inflammable, explosive and dust environment, which has certain safety risks for inspection and maintenance personnel

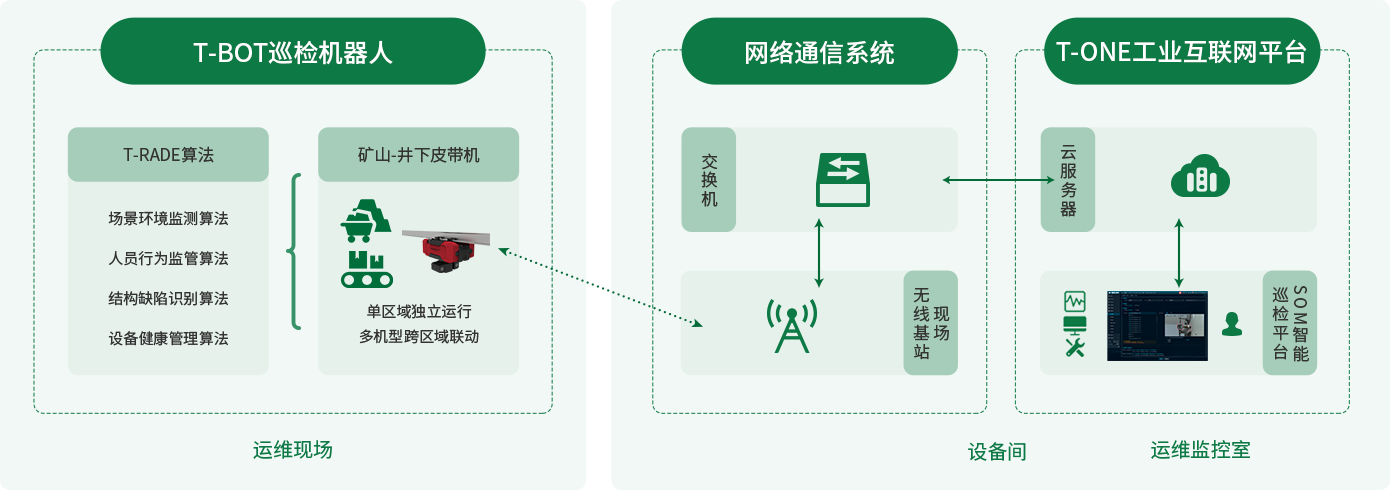

Tianchuang robot mine belt conveyor solution realizes all-round monitoring of belt conveyor corridor working environment and equipment, realizes visual management and implementation of early warning, and improves inspection efficiency and accuracy. Further through the interaction of robots and technicians, the timely processing of abnormal situations is realized. Using big data algorithm to grasp and judge the running status of equipment in time, the full utilization of equipment performance is realized.

Edge cloud collaboration, unified management

Data collection is uploaded in real time to form a digital inspection ledger

Inspection data trend analysis, visual presentation

The inspection work has changed from regular on-site inspection to unmanned, all-weather inspection of equipment status

Create a safe environment and reduce operational risks

Belt deviation, tear monitoring

Early warning of personnel violations

Abnormal temperature monitoring of reducer, roller and roller

Environmental monitoring

Product support

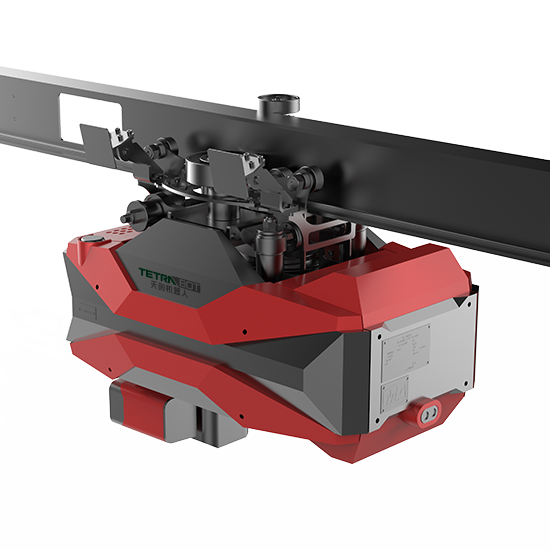

T9-C Hanging Monorail Robot For Mining

The product has mine coal safety certification, explosion-proof and intrinsic safety type. It's equipped with starlight HD camera, infrared thermal imager, gas sensor, ionic smoke, flame detection and other sensors, which can control underground environmental information in real time, and build underground intelligent inspection system.View details

T9-E Intrinsically Safe Hanging Monorail Robot For Mining

The product has the mine intrinsic safety type explosion-proof certification and lightweight design. The body integrates visible light camera, infrared thermal imager, environmental and gas monitoring sensors and other modules to accurately collect and measure the field equipment status and environmental conditions in mines.View details

T-ONE™ SOM Intelligent Inspection Platform

View details

T-RADE Intelligent Algorithm

The T-RADE intelligent algorithm, based on a large amount of experience and technical accumulation in intelligent inspection and operation of segmented scenarios, forms a multi class configurable algorithm model at the application level, forming a powerful AI algorithm library. Ability to quickly deploy and build high-performance AI algorithm application capabilities for enterprises.View details

Application Scenario Case