Belt conveyor is an important part of coal mine transportation in coal preparation plant. Once the fault occurs, it will directly lead to the shutdown of enterprises and cause significant economic losses. Tianchuang robot replaces operation and maintenance personnel in high-frequency and accurate inspection in coal transport treble with strong environmental restrictions and high severity through autonomous mobile explosion-proof rail hanging robot, and breaks through the whole process work system of intelligent inspection and operation, information data collection, visual equipment status presentation, and digital analysis and decision making.

Low Inspection Efficiency

The distance of coal conveyer belt is long, the inspection efficiency is low, the failure occurs, and the reaction timeliness is poor

Harsh Environment

The space of belt conveyor in coal preparation plant is relatively closed, and the noise and dust accumulation are serious during operation

High-Intensity Work

The access area is narrow. Manual inspection has high labor intensity and high safety risk

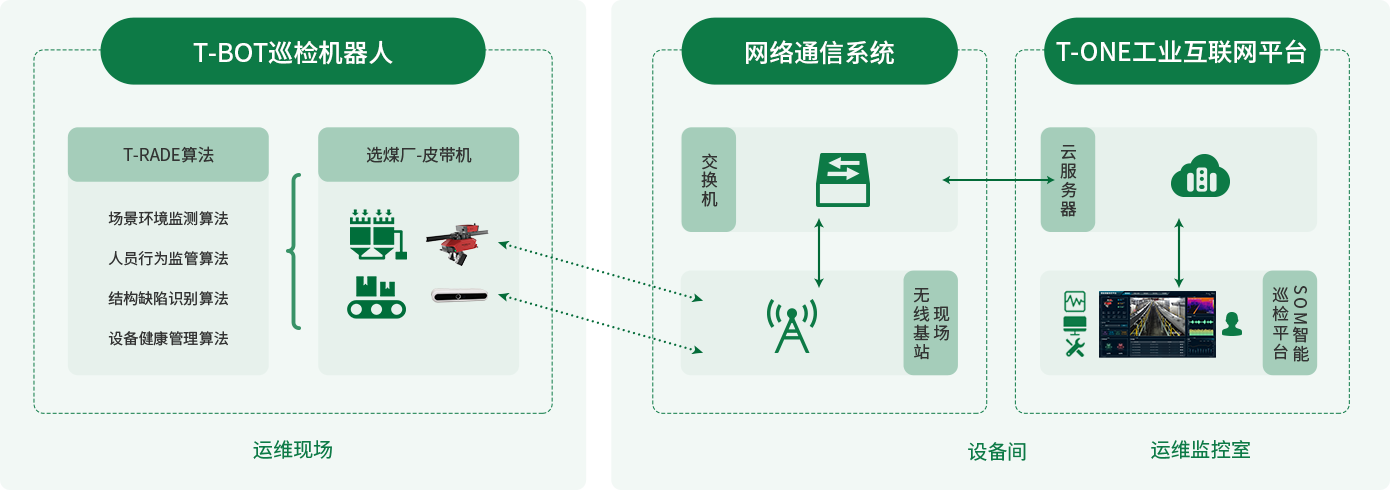

Tianchuang robot coal processing plant belt intelligent inspection solution, with explosion-proof rail hanging robot as the core, cluster coal pipe clogging perception, belt tear perception, belt deviation perception, field temperature and humidity perception, video monitoring, dynamic tracking, infrared temperature measurement and other functions in one intelligent inspection system.

Edge cloud collaboration, unified management

Data collection is uploaded in real time to form a digital inspection ledger

Inspection data trend analysis, visual presentation

The inspection work has changed from regular on-site inspection to unmanned, all-weather inspection of equipment status

Create a safe environment and reduce operational risks

Belt deviation, tear monitoring

Rollers and other components heating monitoring

Early warning of personnel violations

Product support

T9-R Explosion-Proof Hanging Monorail Robot

The product is equipped with HD cameras and infrared thermal imagers, integrated gas detection, temperature and humidity, flame detection and other sensors, realize environmental information monitoring, gas monitoring and other functions as well as data storage, analysis and other 3D display for all Class II explosion-proof scenes.View details

Belt Tear Monitoring Device

View details

Material Flow Monitoring Equipment

View details

T-ONE™ SOM Intelligent Inspection Platform

View details

T-RADE Intelligent Algorithm

The T-RADE intelligent algorithm, based on a large amount of experience and technical accumulation in intelligent inspection and operation of segmented scenarios, forms a multi class configurable algorithm model at the application level, forming a powerful AI algorithm library. Ability to quickly deploy and build high-performance AI algorithm application capabilities for enterprises.View details

Application Scenario Case