Aiming at the characteristics of high temperature, dust and harmful gases in the blast furnace operation area of the ironworks, in order to achieve all-round, whole-process and all-weather effective inspection operation and maintenance control, Tianchuang robot mainly combines AI technology, visual identification technology and motion control technology from the aspects of equipment, safety and tasks. To build a leading intelligent inspection operation and maintenance integrated control system for steel enterprises with core inspection robots.

Low Timeliness

The workload of inspection operation and maintenance personnel is large, the inspection frequency and quality of key areas cannot be guaranteed, and the timeliness of detection information feedback is low

Wrong Detection, Missing Detection

Manual inspection is difficult to manage and standardize, to ensure that the spot inspection is in place, and there will often be missed detection, wrong detection, and false detection

Safety Hazard

The working environment is relatively harsh, special high temperature and harmful gases, and there are certain safety risks for inspection and operation personnel

The intelligent inspection solution of Tianchuang robot blast furnace tuyere platform is mainly composed of robot body unit, system platform, charging unit and communication unit. Comprehensive replacement of manual remote inspection, to achieve intelligent inspection monitoring of production areas and data report management. After an inspection task is completed, an inspection report is generated and information such as the inspection result is stored, facilitating internal data sharing and information traceability.

Edge cloud collaboration, unified management

Data collection is uploaded in real time to form a digital inspection ledger

Inspection data trend analysis, visual presentation

The inspection work has changed from regular on-site inspection to unmanned, all-weather inspection of equipment status

Create a safe environment and reduce operational risks

Monitoring the working condition of tuyere, cooler and air supply pipe

Equipment and sealing surface detection

Pulverized coal pipeline valve status monitoring

Hazardous gas monitoring

Product support

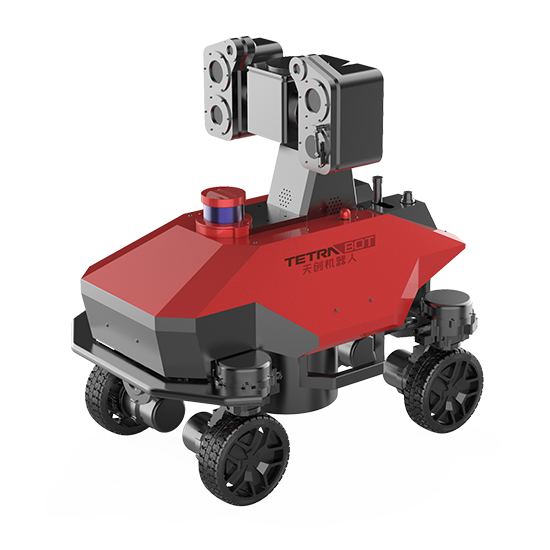

T9-W Explosion-Proof Wheeled Robot

Products have the infrared thermal imaging temperature measurement, laser combustible gas detection, flame detection, and gas concentration detection, and realize autonomous unmanned inspection in the energy hazardous chemical industry.View details

T9-R Explosion-Proof Hanging Monorail Robot

The product is equipped with HD cameras and infrared thermal imagers, integrated gas detection, temperature and humidity, flame detection and other sensors, realize environmental information monitoring, gas monitoring and other functions as well as data storage, analysis and other 3D display for all Class II explosion-proof scenes.View details

Compound Explosion-Proof Multi-Function PTZ

View details

Explosion-Proof Multi-Functional PTZ

View details

T-ONE™ SOM Intelligent Inspection Platform

View details

T-RADE Intelligent Algorithm

The T-RADE intelligent algorithm, based on a large amount of experience and technical accumulation in intelligent inspection and operation of segmented scenarios, forms a multi class configurable algorithm model at the application level, forming a powerful AI algorithm library. Ability to quickly deploy and build high-performance AI algorithm application capabilities for enterprises.View details

Application Scenario Case