Time:2024-06-14

Hubei Longkang Phosphorus Chemical Co., Ltd. is a large-scale mining enterprise integrating centralized mining, sorting and filling. It is committed to building a four-type safety management enterprise that is "resource-saving, mineral-land harmonious, green environmentally friendly, and intrinsically safe".

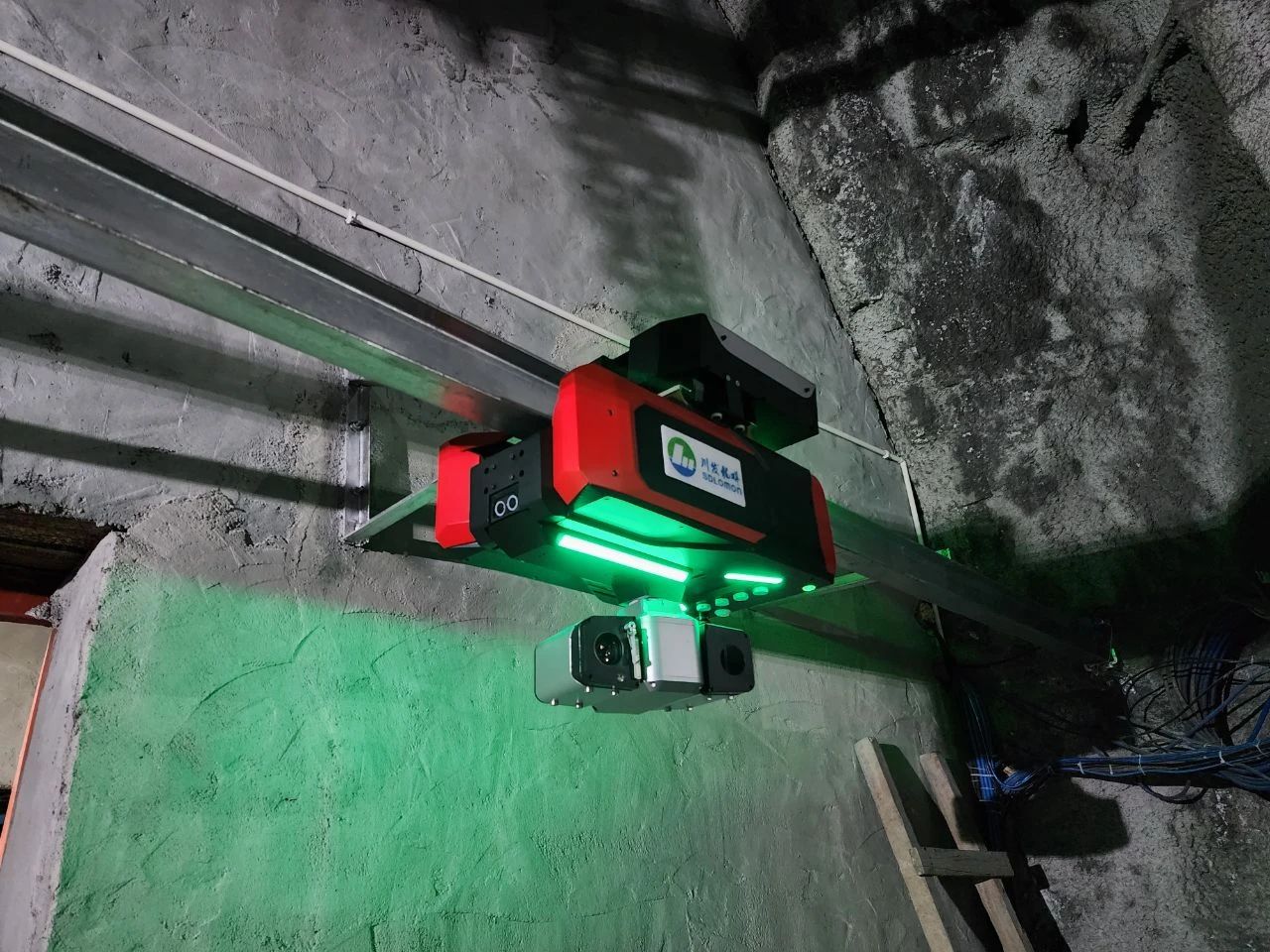

In response to the on-site inspection needs of the central substation under the phosphate mine and the explosion-proof requirements of equipment, Tianchuang Robot uses the T9-E mining intrinsically safe rail-mounted robot to completely replace manual personnel to perform daily inspection tasks, realizing all-weather and intelligent power supply systems in the mine. Detection and monitoring.

Customer Profile

Hubei Longgang Phosphorus Chemical Co., Ltd. is a large-scale mining enterprise engaged in phosphate mining and processing. It has jurisdiction over an underground mine with an annual output of 1 million tons and a supporting gravity selection plant that processes 1 million tons of raw ore.

Project Background

The 830 Central Substation of Hulin Company is located underground in Baizhu Phosphate Mine. It is an "energy station" for the operation of the mine, providing electricity to all underground electrical equipment and facilities.

In the past, personnel on duty needed to manually inspect electrical facilities such as high/low voltage cabinets to ensure the safe and reliable operation of power supply equipment. In order to further improve the efficiency and accuracy of inspection and improve the automation and intelligence level of regional monitoring, this project uses robots to realize round-the-clock intelligent inspection and unmanned inspection of electrical equipment status identification and environmental monitoring in the central substation area under the mine.

Business Challenges

Solutions

In view of the environmental characteristics of the scene such as limited ground space, low illumination, and harmful gases in the operating area of the underground 830 Central Substation of Lake Phosphate Mine, as well as the distribution of high/low voltage electrical cabinet equipment to be monitored on site and the content of key inspection tasks, a set of unmanned operation and maintenance solutions for underground substations are built with Tianchuang T9-E mining intrinsically safe rail-mounted robot as the core, integrating calibration and recognition algorithms, and combining centralized control data platform. Through the robot's online and real-time monitoring of the underground transformation and transportation system, the ground dispatch center can realize remote telemetry and remote control of the operation of power equipment in the area.

The T9-E mining intrinsically safe rail-hanging robot can automatically identify and read the status information of digital meters, indicator lights, knob switches, and protective pressure plates in the high/low power cabinet in the substation area, as well as monitor the temperature and humidity in the environment, carbon monoxide, oxygen content, etc., automatically warn the mine dispatch center in the background if the threshold exceeds, and the operation and maintenance personnel handle it quickly.

The T9-E robot replaces manual labor to complete daily inspection tasks such as equipment operation temperature measurement, instrument data, and control cabinet indicator status reading without affecting the normal operation of on-site system equipment and blocking personnel working channels. Early warning of abnormal situations, avoid the risk of greater accidents. It frees inspection personnel from the harsh working environment, reduces labor costs, ensures the operating efficiency of phosphate ore wells and the safety and reliability of mining equipment operation, and helps Huphosphorus Company build intelligent mines.

The operation and maintenance personnel located in the inouet dispatch center can manage and control the inspection robot to perform inspection tasks online in real time through the system platform, and at the same time transmit the current inspection status and results in real time. An inspection report is generated immediately after the task is completed, and information such as robot inspection pictures and inspection results are stored, so that operation and maintenance personnel can analyze the operation stability characteristics and trends of the underground substation system based on the data, and timely adjust maintenance strategies and work priorities.

Value Effectiveness

Efficient and precise inspection

T9-E completely replaces manual labor to realize remote online precise monitoring of 64 spot inspection positions at the underground central substation and round-the-clock care of 17 electrical equipment, which greatly improves the frequency and quality of inspection inspections, and can promptly discover hidden dangers and fault signs of equipment operation.

Ensure the safety of operators

The putting into use of robots has completely replaced the daily inspection and duty of traditional on-duty high-voltage electricians, realizing the unmanned operation of high-risk positions in underground high-voltage distribution rooms, reducing the investment of personnel on the positions and ensuring the intrinsic safety of the working environment.

Ensure the value of operation and maintenance data

Daily inspection data is classified and stored in real time to facilitate query, statistics and judgment of fault problems. Automatically generate inspection reports or reports to reduce the cost and time of manually selecting useful variables.