The life cycle of photovoltaic power plants is as high as 25 years. Among them, dust pollution is an important factor affecting power generation. It not only reduces the light irradiation of components, but also causes hot spot effect, causes loss of power generation, affects the life of the group price, and causes safety hazards. Tianchuang Robot has rich product delivery experience and implementation operation and maintenance capabilities in the photovoltaic cleaning robot product line.

Improper Cleaning

Photovoltaic power stations have a wide area, a large number, clean water, and the actual power generation efficiency of the panels is only about 60%

Dust Pollution

Including snow, bird droppings, dirt, sand, etc., affecting the power generation efficiency of at least 20%

Hot Spot Effect

It causes high power loss, the component temperature is too high, and the fire that easily burns the component cannot be detected in time

Tianchuang photovoltaic cleaning robot adopts waterless cleaning method and is equipped with self-sufficient power supply of photovoltaic modules and lithium batteries to automatically and independently clean photovoltaic module panel pollution such as ash, snow, and sand. At the same time, the product itself has automatic correction, self-inspection, and anti-fall. and strong wind protection performance, it can operate stably in harsh environments. Support mobile or cloud control, making it convenient and efficient.

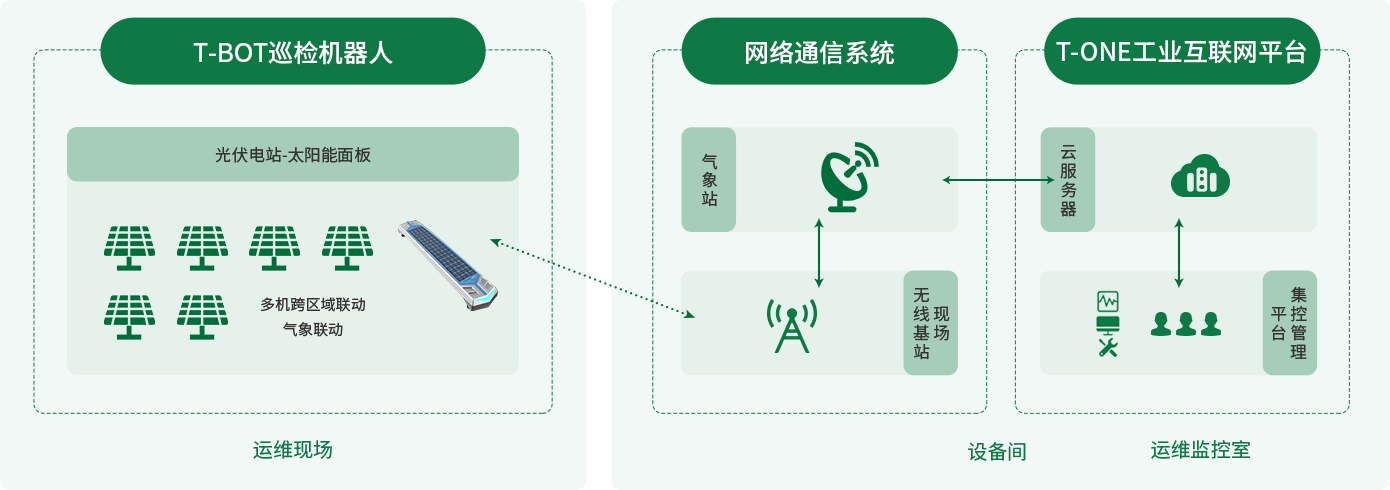

Support global deployment, 10,000 robots real-time concurrent networking connection, linkage control to implement centralized control cleaning operations

Intelligent drive system, with superior obstacle and climbing ability, suitable for complex operating environment

Solar self-powered unit system equipped with fusion high-order cell protection algorithm, no need to take power from the power station, long endurance.

Equipped with an independent motor to drive the cleaning brush, a single cleaning rate of more than 99%

Zero water, cleaning components without damage, through the authority to clean the test components without damage certification

Application Scenario Case