The total installed capacity of Hebei Construction Investment Tangshan Leting Bodhi Island offshore wind farm is 300 megawatts, with a total of 75 wind turbines with a single capacity of 4 megawatts installed, all of which are located at sea level.

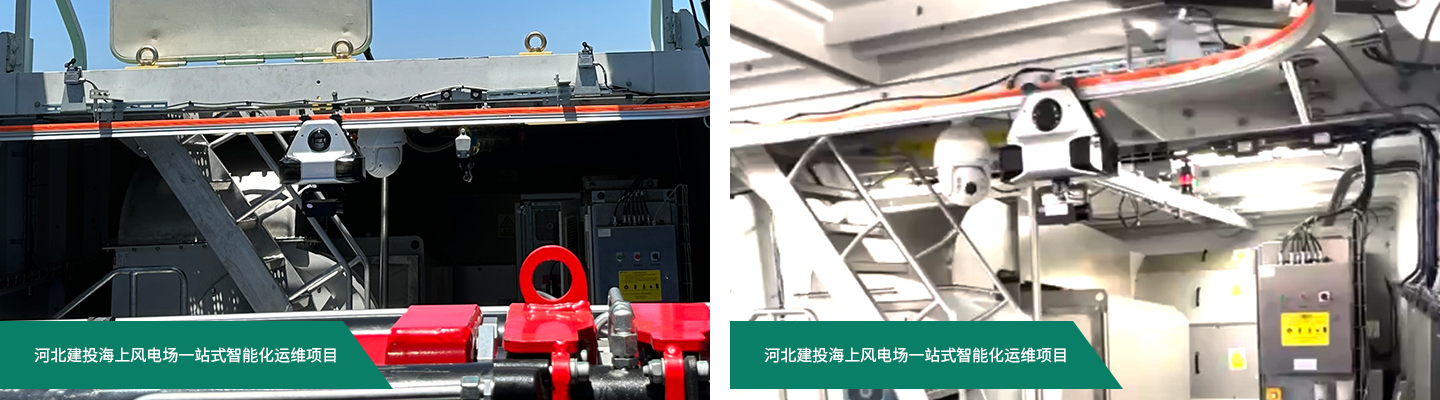

A total of 75 sets of T3-F rail mounted robots have been deployed, covering all wind turbine nacelles of Tangshan Bodhi Island offshore wind farm. They integrate algorithms for equipment health management, scene environment monitoring, structural defect recognition, and meter status reading to quickly and accurately monitor the operation status of on-site equipment. Through the Tianchuang Robot Diagnosis and Warning Platform, periodic statistics and data analysis are conducted to provide data support for predictive maintenance of equipment. Implement a collaborative solution for inspection, operation, and maintenance of wind turbine cabins on the power generation side.

The inspection cycle for wind turbine cabins has been increased from once every two weeks to round the clock inspections, enabling early detection and maintenance of defects and avoiding the escalation of equipment failures caused by delayed defects; The standardization and normalization of inspections have significantly improved, and the quality of inspections is controllable. The planned maintenance rate has increased by 87%, saving 3 million yuan in annual operation and maintenance costs. Assist in the construction of smart wind farm infrastructure and create digital intelligent energy.

Running Time

30min*12 Times/Day

Inspection Point Location

6000 Per Day

Inspection Quantity

75 Offshore Wind Turbine Engine Rooms